Annealing Brass: How It Works, What’s Actually Happening, and Why Methods Behave Differently

By Aaron Peterson — Founder, Hawkeye Ammosmithing

“Data-driven ballistics, tested & proven.”

“Data-driven ballistics, tested & proven.”

Preface: Why This Article Exists

This article is a technical companion to Annealing Brass: What It Is, Why People Do It, Why People Don’t — and Why Results Vary So Much. Find it here: https://hawkeyeammosmithing.com/thr...people-dont-and-why-results-vary-so-much.142/The goal here is not to tell anyone they are annealing “wrong,” nor to promote or dismiss any specific method. Instead, this article explains what is physically happening during annealing, how different annealing methods deliver energy to cartridge brass, and why those methods inherently differ in capability, control, and limitations.

Understanding how annealing works makes it much easier to understand why people see different results—and why reasonable people can arrive at different conclusions.

What Annealing Means in Metallurgical Terms

Cartridge brass work-hardens as it is plastically deformed. In normal reloading, this occurs primarily during:

- firing (neck expansion),

- resizing (neck reduction),

- and repeated cycling of those two steps.

- increased neck springback,

- inconsistent sizing behavior,

- increased brittleness,

- and eventual cracking.

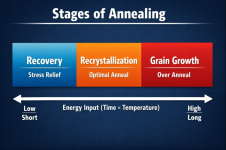

The Three Stages of Annealing (Conceptual Overview)

1. Recovery

- Internal stresses are relieved

- Dislocation structures partially rearrange

- Minimal reduction in hardness

2. Recrystallization

- New, strain-free grains form

- Significant hardness reduction occurs

- Ductility is restored

3. Grain Growth

- Existing grains grow excessively

- Strength drops further

- Brass becomes overly soft

Time and Temperature: Why Both Matter

One of the most common misconceptions in annealing is treating temperature as the goal.

In reality, annealing depends on both time and temperature together:

- Higher temperatures require less time

- Lower temperatures require more time

- Brass does not instantly become “dead soft” upon reaching a specific temperature

This is why:

- visual cues alone can be misleading,

- chasing a single temperature number often produces inconsistent results,

- and different annealing methods behave very differently.

How Energy Is Delivered: The Real Difference Between Annealing Methods

The most important difference between annealing methods is how energy is delivered to the brass, not simply how hot the heat source is.

Torch / Flame Annealing

(Radiation and Conduction)

Torch annealing applies heat externally through:

- radiant heat from the flame,

- and conduction as heat enters the brass surface.

Characteristics

- Energy delivery depends on flame size, shape, and position

- Dwell time is controlled by the operator or a mechanical system

- Gas pressure, airflow, and setup consistency all matter

Strengths

- Simple and accessible

- Flexible across cartridge types

- Capable of good results with disciplined setup

Limitations

- Highly dependent on repeatability

- Sensitive to environmental conditions

- Small timing variations can produce meaningful differences

Salt Bath Annealing

(Conduction-Based Heating)

Salt bath annealing transfers heat through direct contact with molten salt. This method is fundamentally different from flame and induction approaches.

What Salt Bath Annealing Typically Achieves

Salt bath annealing of cartridge brass primarily achieves the recovery stage of annealing:

- Internal stresses are relieved

- Dislocation structures partially rearrange

- A small reduction in hardness may occur

Why Salt Bath Annealing Is Inherently Limited

To achieve recrystallization, brass requires:

- sufficient energy input,

- delivered over an appropriate time window,

- concentrated in the neck and shoulder only.

1. Energy Density and Time

Salt baths operate at relatively moderate temperatures and rely on conduction, which is inherently slower and less energy-dense than flash methods. Achieving recrystallization would require longer dwell times.

2. Heat Migration Into the Case Body

Because heat is transferred through contact and conducted internally, longer dwell times allow heat to:

- migrate down the case body,

- soften areas that should remain hard.

- short dwell → recovery only

- long dwell → risk of annealing the case body

3. Brass as a Heat Sink

When brass is immersed, it acts as a localized heat sink, reducing the temperature of the salt immediately surrounding it. While the bath recovers overall temperature, this interaction works against rapid, localized recrystallization.

Why This Matters in Practice

Recovery alone can:

- reduce internal stress,

- slightly reduce hardness,

- improve uniformity to a degree.

- fully reset neck hardness,

- reliably normalize springback,

- establish a consistent baseline hardness comparable to recrystallization-based flash annealing.

This is not a criticism of users—it is a limitation of the mechanism.

Neutral Summary

Salt bath annealing is best understood as a stress-relief method, not a full neck-and-shoulder annealing solution. Whether that limitation matters depends entirely on the reloader’s goals.

Induction Annealing

(Electromagnetic Energy Generation)

Induction annealing generates heat within the brass itself through electromagnetic coupling.

Characteristics

- Energy generation depends on material mass, geometry, and coil design

- Heat is localized and rapid

- Highly repeatable once parameters are set

Strengths

- Reduced environmental sensitivity

- High repeatability potential

- Fast, controlled energy delivery

Limitations

- Setup still matters

- Different cartridges respond differently

- Requires understanding cartridge-specific behavior

Why “Same Settings” Rarely Transfer Perfectly

Cartridges differ in:

- neck thickness,

- neck length,

- shoulder mass,

- alloy hardness,

- work history.

What a “Full Anneal” Actually Means

Not all annealing methods reach the same stage of annealing.

- Some primarily reach recovery

- Some reliably reach recrystallization

- Some can enter grain growth if misapplied

Where Inconsistency Is Most Often Introduced

Across all methods:

- inconsistent dwell time

- changing brass lots without reassessment

- relying solely on visual cues

- annealing after sizing

- mixing headstamps

- inconsistent neck condition

How This Article Pairs With the Master Article

- Master article: Why annealing matters (or doesn’t)

- This article: How annealing works and why methods differ

Frequently Asked Questions

Does salt bath annealing work?

Yes—for stress relief (recovery). It does not reliably achieve full recrystallization without unwanted side effects.

Is recovery-only annealing useless?

No.

Recovery can improve uniformity and reduce brittleness. It simply does not reset neck hardness to the same degree as recrystallization.

Can longer salt bath dwell times fix this?

Longer dwell times increase the risk of softening the case body, which is undesirable and potentially unsafe.

Is visible glow always bad?

No.

Cartridge brass begins glowing around ~950°F. Duration matters as much as temperature.

Does seeing a visible glow and removing the case immediately mean it was properly annealed?

Not necessarily.

A visible glow simply indicates that the brass has reached a temperature high enough to emit visible light (roughly around 900–950°F in low ambient light). While temperature is one component of annealing, annealing is a function of both time and temperature together.

Reaching a glowing temperature for an extremely brief moment does not guarantee that the brass has:

- completed recrystallization, or

- reached a consistent and repeatable final hardness.

This is why relying solely on visual glow as an annealing indicator can be misleading. Glow can be a data point, but it is not a definitive measure of a proper anneal by itself.

Is Tempilaq a reliable way to determine a proper anneal?

Tempilaq can be useful as a minimum temperature indicator, but it does not measure final hardness and was not designed specifically for flash annealing cartridge brass.

The color change is subjective, timing-sensitive, and does not account for how long the brass remains at temperature. Two cases can both trip Tempilaq and still end up with very different hardness depending on dwell time and energy delivery.

Tempilaq can help avoid under-heating, but it does not guarantee a proper or repeatable anneal.

If annealing works, why don’t I always see lower SDs or smaller groups?

Because annealing removes only one source of variation.

If other variables dominate—such as:

- inconsistent brass volume,

- inconsistent neck thickness,

- seating variation,

- rifle or shooter limitations,

Can annealing make brass worse if done incorrectly?

Yes.

Inconsistent annealing can:

- increase variation in neck hardness,

- introduce inconsistent springback,

- and reduce predictability in sizing and bullet release.

Does annealing fix inconsistent brass or mixed headstamps?

No.

Annealing can help normalize work-hardening, but it does not make different brass identical. Differences in:

- alloy,

- thickness,

- geometry,

- and manufacturing process

Is it possible to over-anneal brass without melting it?

Yes.

Grain growth can occur well below the melting point of brass if the material is held at high temperature for too long. Over-annealed brass may appear normal visually but can exhibit:

- excessive softness,

- reduced strength,

- shortened case life.

Why do some people anneal every firing while others don’t?

It comes down to goals and process.

Annealing every firing can:

- maximize consistency,

- minimize springback variation,

- simplify sizing setup.

- their application doesn’t demand it,

- they retire brass early,

- or the added process step isn’t worth the return.

Is annealing necessary for hunting ammunition?

Sometimes—but often not.

At typical hunting distances and accuracy requirements, annealing may not produce a noticeable difference. For long-range hunting or situations where extreme consistency is desired, annealing can provide added confidence by removing one variable from the system.

Does annealing affect pressure or velocity directly?

Annealing affects neck tension consistency, which can influence pressure and velocity variation. It does not directly increase or decrease pressure by itself, but inconsistent annealing can contribute to inconsistent pressure behavior.

Does quenching harden brass?

No.

Brass does not harden when quenched. Quenching only cools it faster.

Should I anneal before or after sizing?

Before sizing. Annealing affects springback and sizing behavior.

Do I need to anneal every firing?

Not necessarily. Frequency matters less than consistency.

Is induction inherently “better”?

Induction offers greater repeatability potential, but no method is immune to poor setup or misunderstanding.

Final Thoughts

Annealing methods should be evaluated not by tradition or popularity, but by what stage of annealing they reliably achieve and whether that outcome aligns with the reloader’s goals.

Once the mechanisms are understood, most annealing debates resolve themselves.

Aaron Peterson

Founder – Hawkeye Ammosmithing

Data-Driven Ballistics, Tested & Proven

Founder – Hawkeye Ammosmithing

Data-Driven Ballistics, Tested & Proven