Apex Afterburner (lathe-turned mono) — Construction Review & First Impressions

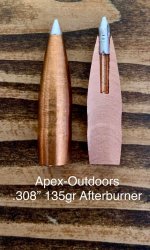

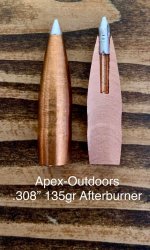

TL;DR: Apex’s new lathe-turned monolithic Afterburner is a promising petal-shedding copper hunting bullet. Long, wide cavity + broaching + a relatively soft copper alloy produce clean petal separation and leave a slim, flat shank that retains velocity and penetrates well. Early terminal reports and my initial cut/load work look good; follow-up field reports and gel/recovered-shot threads will come next.

Intro / Why this matters

As many of you know, bullet construction and terminal ballistics are a passion of mine. Monolithic copper bullets that intentionally *shed* petals (rather than retain them) are an important new approach to delivering both early tissue disruption and sustained penetration. Makers in this space include LeHigh Defense, Cutting Edge, Hammer, Badlands Precision, and now Apex-Outdoors. I ordered a box of the 135 gr .308” Apex Afterburners on release, worked up loads, and sectioned one to inspect construction.

What I did

Initial findings — construction & materials (detailed)

Terminal mechanics — how these work in practice

The Afterburner (and similar shed-petal monos) operate via a two-stage process:

This results in both large early disruption (petals) and deep, narrow penetration (shank) when it functions as designed.

How Apex compares to other brands

Why shedding petals can be effective (mechanics & energy transfer)

When a monolithic sheds petals cleanly it:

This sequence—fast expansion, weight shedding, then shank penetration—can produce superior energy transfer if reliably executed.

Practical notes & limitations

What I still need to validate (next posts planned)

Author verdict (first impressions)

TL;DR: Apex’s new lathe-turned monolithic Afterburner is a promising petal-shedding copper hunting bullet. Long, wide cavity + broaching + a relatively soft copper alloy produce clean petal separation and leave a slim, flat shank that retains velocity and penetrates well. Early terminal reports and my initial cut/load work look good; follow-up field reports and gel/recovered-shot threads will come next.

Intro / Why this matters

As many of you know, bullet construction and terminal ballistics are a passion of mine. Monolithic copper bullets that intentionally *shed* petals (rather than retain them) are an important new approach to delivering both early tissue disruption and sustained penetration. Makers in this space include LeHigh Defense, Cutting Edge, Hammer, Badlands Precision, and now Apex-Outdoors. I ordered a box of the 135 gr .308” Apex Afterburners on release, worked up loads, and sectioned one to inspect construction.

What I did

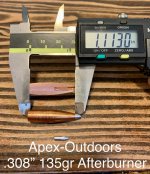

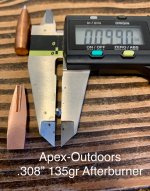

- Bought a release box (135 gr .308).

- Performed load development and accuracy checks.

- Sectioned a single bullet to inspect cavity geometry, broaching, tip fit, and alloy hardness.

Author observation: these are initial construction / first-impression notes. I’ll post detailed terminal performance (recovered shots / gel tests / chronograph & BC data) in follow-up threads.

Initial findings — construction & materials (detailed)

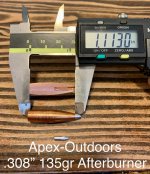

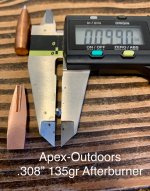

- Cavity length: nearly half the bullet length (excluding tip). This long cavity weakens the ogive area, allowing the nose to deform / reliably open even at lower impact velocities.

- Cavity diameter: relatively wide — helps internal hydraulic pressure build quickly so the nose opens cleanly and reliably.

- Cavity mouth & bevel: the mouth is beveled; tip seats into that bevel. There’s a slight flat on the tip front so the tip digs in and drives back into the cavity on impact.

- Broaching: broaching is evident near the tip / mouth and creates weakened areas that control where the copper splits — deliberate weak points → predictable petal formation. The broaching does not run the entire cavity length.

- Material / hardness: the copper cut easily; it appears to be a relatively soft alloy. That softness (within reason) helps predictable expansion and clean petal separation. My cut was easier than many monos I’ve sectioned.

- External profile / BC considerations: Apex Afterburners do not use multiple drive bands; they use a bore-rider style bearing surface to control engraving forces without creating parasitic drag. That keeps them more aerodynamic than many swaged / drive-band monos.

Terminal mechanics — how these work in practice

The Afterburner (and similar shed-petal monos) operate via a two-stage process:

- Rapid expansion & petal formation — long/wide cavity + broaching reduces the energy needed to split petals and produces a strong, fast hydraulic impulse.

- Petal shedding → compact shank penetration — once petals separate, the remaining flat-front shank has a much smaller frontal area and retains velocity better, continuing to penetrate deeply and delivering sustained hydraulic force.

This results in both large early disruption (petals) and deep, narrow penetration (shank) when it functions as designed.

How Apex compares to other brands

- LeHigh: historically one of the originals for petal-shedding monos; effective but many LeHigh profiles are swaged and less aerodynamic. Apex appears to retain more shank mass and a sleeker lathe-turned ogive.

- Cutting Edge / Badlands / Barnes / Hornady CX / Nosler E-Tip: many of these retain petals or are swaged; retained petals increase frontal area after expansion and often slow the bullet earlier. Apex’s shed-then-shank approach retains more forward energy at distance.

- Hammer: earlier Hammer designs (in my experience) had narrow cavities, overly soft alloys, drive bands/open tips, and aerodynamic compromises. That caused inconsistent expansion and poor BC retention. Edited note: Hammer now has a tipped Hammer Hunter and increased cavity size in revisions — initial changes look like improvements.

- Apex standouts: long + wide cavity, broaching for controlled petal formation, beveled mouth & driven tip, bore-rider (no parasitic drive bands) — a clean internal/external balance.

Author observation: competitor designs are evolving quickly; Apex currently appears to have a balanced approach addressing both terminal mechanics and external ballistics better than many alternatives I’ve tested so far.

Why shedding petals can be effective (mechanics & energy transfer)

When a monolithic sheds petals cleanly it:

- Generates large internal hydraulic pressure and a big early impulse as petals open;

- Sheds light petals quickly so the remaining shank has a reduced frontal area;

- Allows the shank to retain velocity and drive deeper, creating sustained hydraulic force rather than being immediately blunted.

This sequence—fast expansion, weight shedding, then shank penetration—can produce superior energy transfer if reliably executed.

Practical notes & limitations

- Advertised minimum impact velocity: Apex advertises petal shedding down to ≈1650 fps. That’s useful, but always confirm with your own loads & recovered shots.

- BC & long-range retention: lathe-turned profile + no drive bands = better BC retention vs many swaged monos; that helps terminal performance at range.

- Angle sensitivity: beveled mouth and tip seating help initiate opening on oblique hits — Apex geometry appears less likely to fail on angled impacts vs older designs.

- Lead-free advantage: no lead — useful where lead is restricted and avoids lead-contamination concerns for recovered gut piles.

- Price: lathe-turned monolithics are expensive; Apex pricing currently makes me cautious about using them as a daily go-to. If prices normalize, adoption will be easier.

What I still need to validate (next posts planned)

- Expanded recovered-shot dataset across ranges/angles/animals.

- Gelatin / calibrated media penetration testing.

- Lot-to-lot manufacturing consistency checks.

- Long-term accuracy matrix vs my regular lead-core favorites.

Author verdict (first impressions)

Promising and thoughtfully engineered. My cut and load work supports positive terminal reports I’ve seen: the long, wide cavity, broaching, bevel, and softer copper all appear intentionally designed to shed petals cleanly and leave an aerodynamic shank for penetration. Not yet my daily default only because of price and because I want a larger, controlled terminal dataset — but I’d use these confidently where lead is restricted or when pricing/availability make sense.